How AI Automation Is Changing Online Businesses?

TL;DR

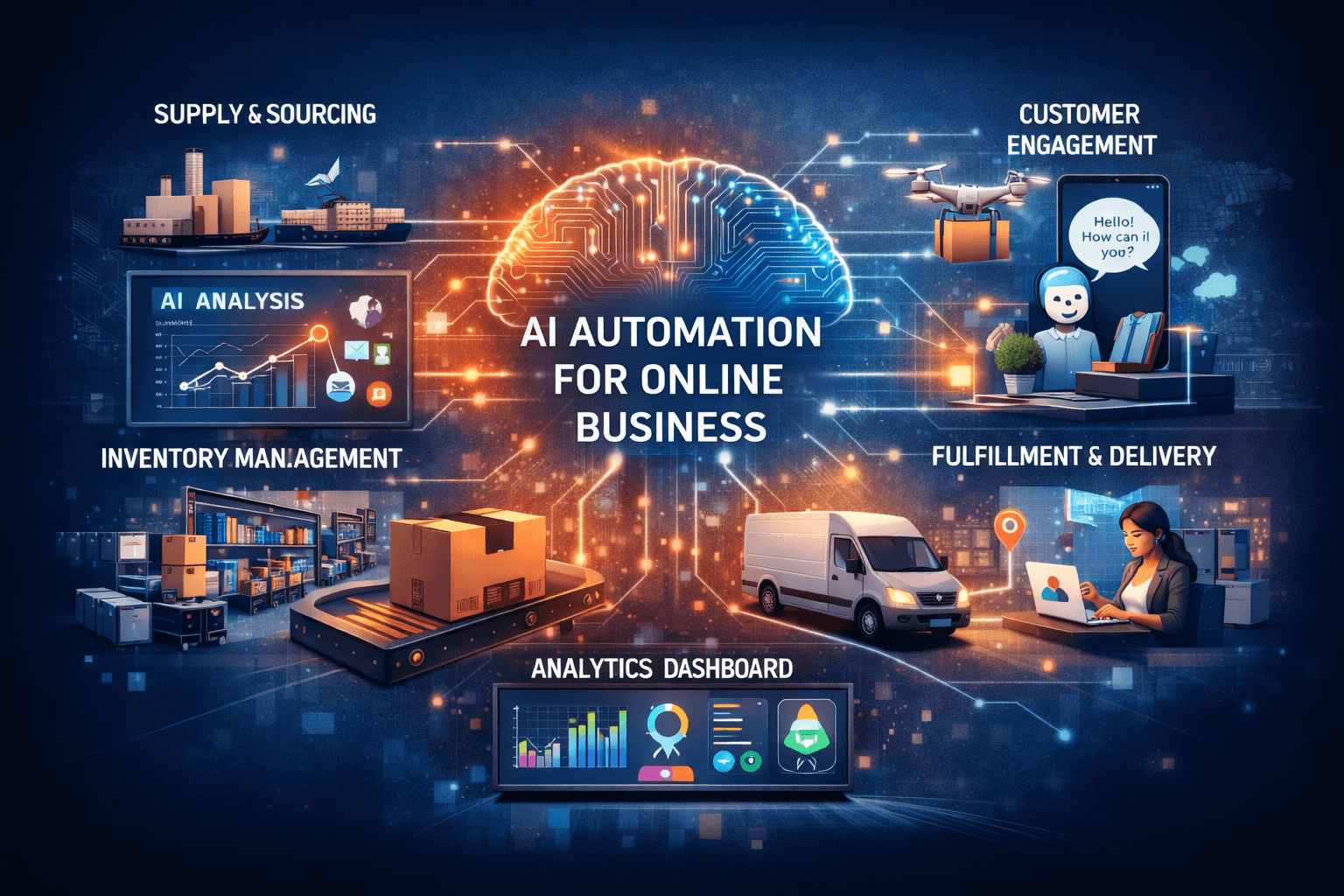

AI automation is transforming how online businesses operate, from sourcing and inventory to fulfillment and customer engagement. By leveraging predictive analytics, real-time tracking, and intelligent workflows, companies can boost demand forecasting by up to 40%, reduce logistics costs, minimize errors, and enhance customer experience. Integrated AI systems enable end-to-end visibility, sustainable operations, and continuous optimization across the entire online business’s lifecycle.

Online Business rarely collapses because of poor marketing. It breaks under operational pressure.

Missed demand forecasts. Overstocked warehouses. Delayed deliveries. Customer support bottlenecks.

These friction points compound as businesses scale. What used to work at 100 orders a day simply does not hold up at 10,000.

This is where ai automation is no longer optional. It is becoming the operational backbone of modern online businesses.

Where AI Automation Works for Online Businesses?

Across sourcing, inventory, fulfillment, and post-purchase support, AI-driven automation is reshaping how online business runs; often invisibly, but with measurable impact. Companies adopting these systems are seeing up to 40% gains in demand forecasting accuracy and significant reductions in logistics and holding costs through predictive analytics.

What makes this shift different from earlier automation waves is scope. AI is not optimizing isolated tasks. It is learning the entire online business lifecycle.

From Reactive to Predictive: How AI Automation Is Rewriting Online Business Operations

Traditional online business operations react to problems after they appear. AI-powered automation flips this logic.

Instead of responding to stockouts, AI predicts them. Instead of scrambling during supplier disruptions, it flags risk weeks in advance. Instead of handling customer complaints after frustration sets in, it intervenes proactively.

This predictive capability is what allows AI to “take the place” of manual decision-making across complex systems.

Let’s look at how this plays out across key online business functions.

Smarter Supply and Sourcing Decisions

Sourcing has always been one of online business’s weakest links. Supplier delays, demand volatility, and geopolitical disruptions can derail entire catalogs.

AI-driven online business automation addresses this by continuously analyzing:

• Historical sales data

• Market and pricing trends

• Weather patterns

• Social media signals

• Supplier performance history

This allows platforms to forecast demand with far greater precision and identify which suppliers are most critical to operations.

Some AI systems can detect early warning signs such as financial instability or delivery inconsistency in suppliers, enabling businesses to renegotiate contracts, diversify sourcing, or shift volumes proactively.

Walmart’s use of AI in supplier negotiations is a well-known example. By using predictive analytics to understand pricing trends and supplier risk, they improve margins while maintaining supply continuity.

This is no longer about choosing the cheapest supplier. It is about choosing the most resilient one.

Inventory Management That Actually Matches Demand

Inventory is where capital goes to sleep—or disappears.

AI-powered inventory automation tracks stock levels in real time and predicts future demand using historical sales, seasonality, promotions, and external signals. This enables automated reordering that aligns inventory with expected order volumes, not guesswork.

The impact is immediate:

• Reduced stockouts during high-demand periods

• Lower holding costs from overstock

• Fewer emergency replenishments

In warehouses, AI-driven robotics and layout optimization improve picking efficiency, while machine learning models refine storage placement based on movement patterns.

Instead of static stock rules, inventory becomes adaptive.

For online business businesses operating across multiple channels, this alignment can be the difference between growth and cash flow collapse.

Faster, Cleaner Order Processing

Manual order processing is slow, error-prone, and expensive to scale.

AI automates order verification, inventory checks, backorder handling, and status updates without human intervention. Orders are validated against real-time stock data, reducing cancellations and fulfillment errors.

AI-powered sorting and packing systems further reduce mistakes by matching items accurately and optimizing packaging based on order composition.

Returns, often treated as a cost center, are also being automated. By analyzing return patterns, AI systems can flag quality issues, optimize inspection workflows, and accelerate restocking cycles.

The result is faster fulfillment with fewer operational leaks.

Fulfillment and Delivery That Adjusts in Real Time

Delivery failures are often blamed on logistics partners, but routing inefficiency and poor forecasting play a huge role.

AI-driven fulfillment platforms optimize routes by factoring in traffic, weather, fuel costs, and delivery constraints. Schedules are dynamically adjusted to reduce delays and emissions.

Predictive logistics tools like FourKites go a step further by forecasting disruptions before they occur. They simulate scenarios, identify risk points, and recommend rerouting options to maintain delivery promises.

This kind of adaptive logistics is especially critical for last-mile delivery, where margins are thin and customer expectations are unforgiving.

When AI runs fulfillment, delivery becomes a controlled variable—not a gamble.

Customer Engagement Without the Wait Times

Customer experience is no longer limited to the storefront. It extends into delivery updates, return handling, and post-purchase communication.

AI chatbots and virtual agents now handle a large share of customer interactions, offering:

• Real-time shipment updates

• Order modifications

• Personalized product recommendations

• 24/7 support coverage

More importantly, AI systems analyze sentiment and behavior patterns to predict churn and dissatisfaction. This allows businesses to intervene early with proactive outreach or tailored offers.

Virtual try-on technologies also play a role here, reducing returns by improving size and fit accuracy before purchase.

Customer engagement shifts from reactive support to continuous experience management.

One System, End-to-End Visibility

What truly sets online business automation using AI apart is integration.

Modern AI dashboards provide end-to-end visibility across sourcing, inventory, fulfillment, and customer engagement. They simulate how changes in one area impact the entire network—whether that is cost, sustainability, or delivery speed.

Generative AI is simplifying how teams interact with these systems, replacing complex interfaces with conversational planning tools. Instead of digging through reports, teams can ask direct questions and receive actionable insights.

Machine learning continuously refines processes, from sustainable routing decisions to cost optimization strategies.

Operations stop being siloed. They become interconnected and continuously improving.

Conclusion

online business scale has outgrown human-only operations.

As order volumes rise, customer expectations tighten, and supply chains become more fragile, AI-driven automation becomes the only viable way to maintain control without inflating costs.

This is not about replacing people. It is about replacing inefficiency.

online business automation using AI is taking the place of reactive decision-making with predictive systems that learn, adapt, and optimize continuously. Businesses that adopt this shift early gain resilience. Those that delay feel the pressure in margins, customer trust, and operational burnout.

The quiet truth is this:

The future of online business will not be built on faster marketing. It will be built on smarter operations.

We at Glance are enhancing the online shopping experience by letting customers see how outfits look on them before buying. This virtual try-on feature brings confidence and convenience to every purchase.

FAQs Related to Online Business Automation with AI

- Which online business functions benefit most from AI automation?

The online business functions that benefit most from AI automation are demand forecasting, inventory management, order processing, fulfillment, logistics, and customer engagement. AI excels where large data volumes and repeated decisions exist. By analyzing historical sales, real-time signals, and behavioral patterns, AI automates planning, reduces human error, and improves operational speed across the entire online business lifecycle. These gains directly translate into lower costs, faster delivery, and more consistent customer experiences.

2. What are examples of AI automation tools used for demand forecasting and inventory management?

Common AI automation tools for demand forecasting and inventory management include predictive analytics platforms, machine learning forecasting engines, and AI-powered inventory optimization systems. Tools used by retailers analyze sales history, seasonality, promotions, weather, and social signals to predict future demand accurately. Platforms like Blue Yonder, Netstock, and SAP AI-driven planning systems help businesses automate reordering, reduce stockouts, and prevent overstock, improving inventory alignment with actual customer demand.

3. How does AI automation optimize warehouse layout, picking, and robotics?

AI optimizes warehouse operations by analyzing item movement frequency, order patterns, and space utilization. Machine learning models recommend optimal product placement to reduce picker travel time and improve throughput. AI-driven robotics use computer vision and real-time routing to automate picking, sorting, and packing with high accuracy. These systems continuously learn from order flow, adjusting layouts and robotic paths to improve efficiency and reduce fulfillment errors as demand changes.

4. What AI automation techniques are used for dynamic pricing and rate prediction in online business?

AI techniques for dynamic pricing include machine learning models, demand elasticity analysis, and real-time competitive benchmarking. These systems analyze customer behavior, market conditions, inventory levels, and competitor pricing to adjust prices automatically. Predictive rate models forecast how price changes impact conversions and margins, allowing online business businesses to remain competitive while protecting profitability. This approach replaces static pricing with adaptive, data-driven decision-making.

5. How does AI automation improve returns processing and reverse logistics?

AI improves returns processing by analyzing return reasons, customer behavior, and product data to identify patterns and root causes. Automated systems classify returns, prioritize inspections, and recommend restocking, resale, or liquidation paths. Predictive analytics also help reduce future returns by improving size recommendations and product descriptions. In reverse logistics, AI optimizes routing and consolidation, lowering processing costs and accelerating the return-to-inventory cycle.